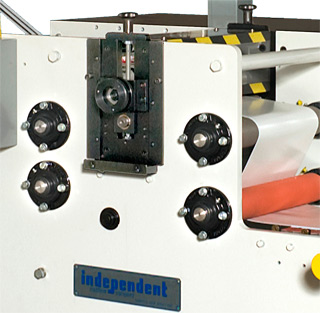

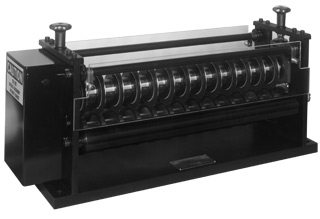

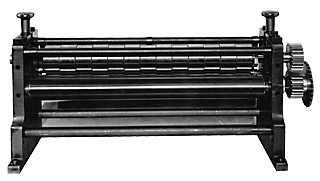

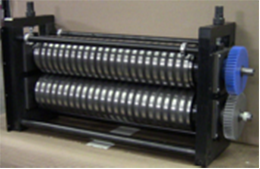

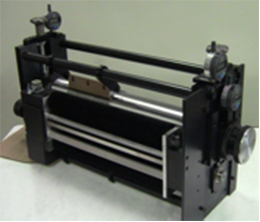

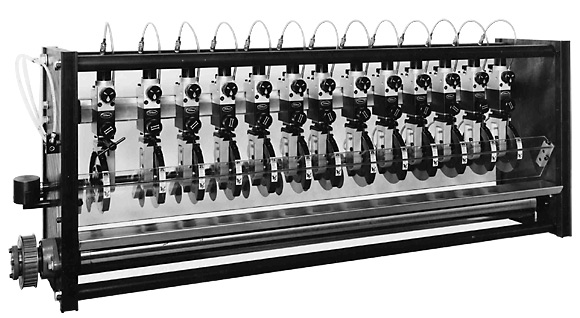

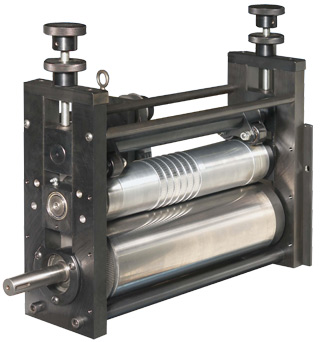

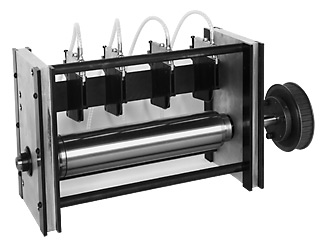

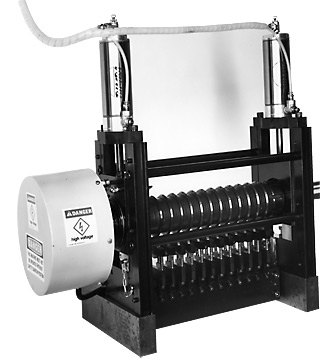

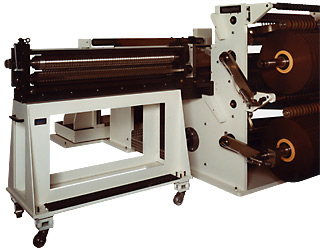

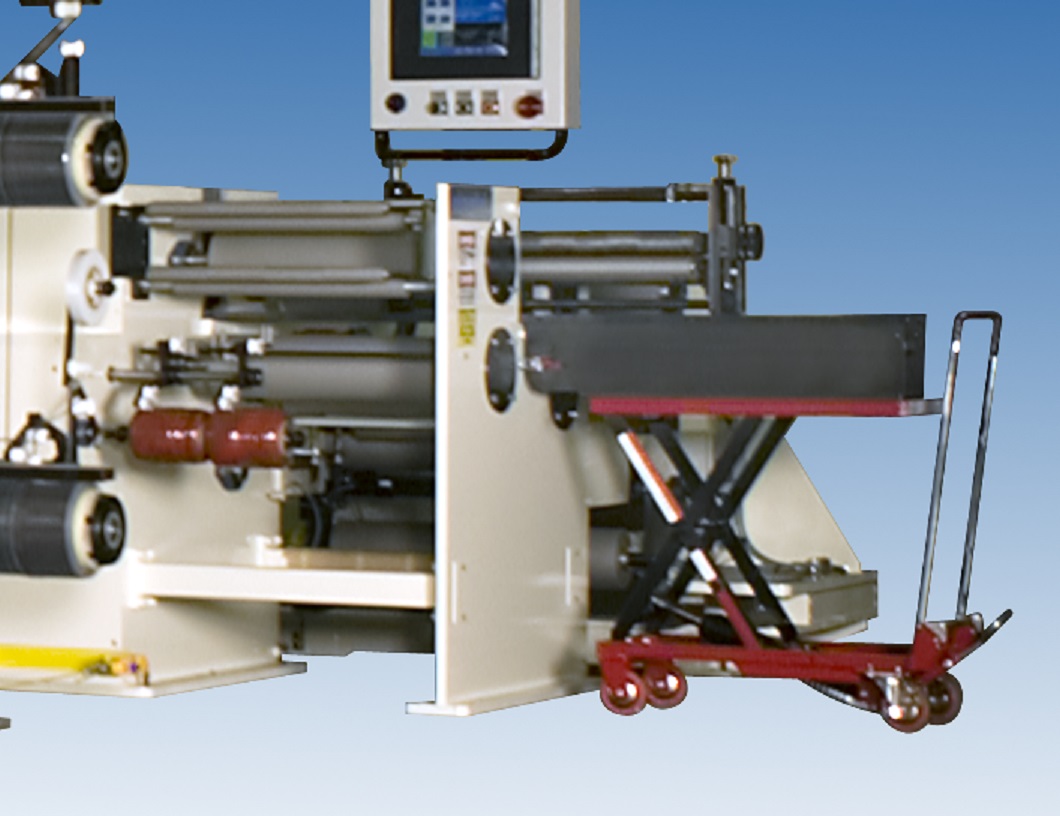

Interchangeable Slitting Heads

Don’t be locked into one or two slitting methods!

The IMC interchangeable slitter assembly provides versatility for current and future converting requirements. Our interchangeable slitting assemblies can also supplied as modular units to work inline with already existing process.

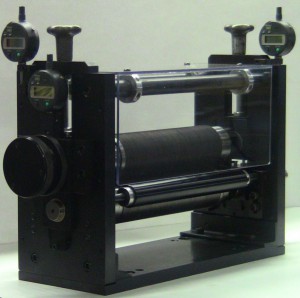

Basic Slitting Methods

There are 5 basic techniques that are used to slit most flexible materials: shear, razor, score, rotary die & hot knife. Because each has its pros and cons there is no single method that can be universally used for the wide range of applications most converting operations encounter. For this very reason, IMC offers the exclusive ”interchangeable” slitting assemblies with most slitting machinery. The interchangeable assembly enables our converting equipment to have the flexibility necessary for the challenges of current and future requirements. Speak with our application engineers to determine which methods are best suited to your needs.